Municipal engineering machinery and equipment quality control

We provide various types of Municipal engineering machinery and equipment. If you need customization, please feel free to contact us.

How do we manage and improve the quality of machinery and equipment

Rigorous raw material selection and testing

- Supplier selection: Establish a long-term and stable cooperative relationship after carefully understanding the reputation, scale and other information of raw material suppliers to ensure consistent raw material supply quality for engineering machinery and equipment.

- Standardized testing standards: Different construction machinery and equipment use different raw materials and accessories. We will formulate strict standardized testing standards to ensure that different batches of different models of construction machinery and equipment have the same performance.

- Implement sampling testing: Before starting the manufacturing of engineering machinery and equipment, we will conduct sampling testing of raw materials and accessories to ensure that the batch of raw materials meets the performance indicators of equipment manufacturing.

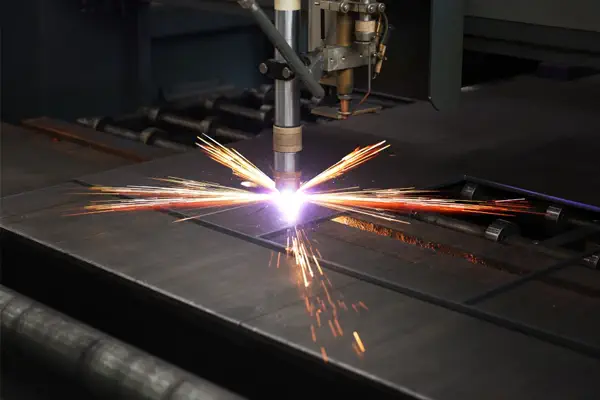

Steel plate cutting

- Cutting equipment calibration: We use laser cutting machines to cut steel plates. The laser cutting machines are calibrated before cutting to ensure that the cut steel plates meet production requirements.

- Cutting process control: During the operation of the laser cutting machine, we will strictly control the cutting speed, laser power, cutting angle and other operating parameters to ensure that the finished product after cutting meets the design specifications

- Standardized cutting process: We regularly conduct skills training for laser cutting machine operators to improve their professional skills while ensuring the quality of relevant components of engineering machinery and equipment.

Raw material welding quality control

- Material preparation before welding: When welding steel plates for engineering machinery and equipment, we will clean the dirty raw materials to ensure that there is no oil or rust at the welding point of the steel plates.

- Welding equipment testing: We have dedicated personnel to conduct regular testing of welding equipment to ensure that the welding equipment can work properly and maintain the consistency and stability of the welding process.

- Ultrasonic inspection: After welding is completed, we will use ultrasonic flaw detection tools to inspect the welded parts to ensure that there are no leaks or bubbles.

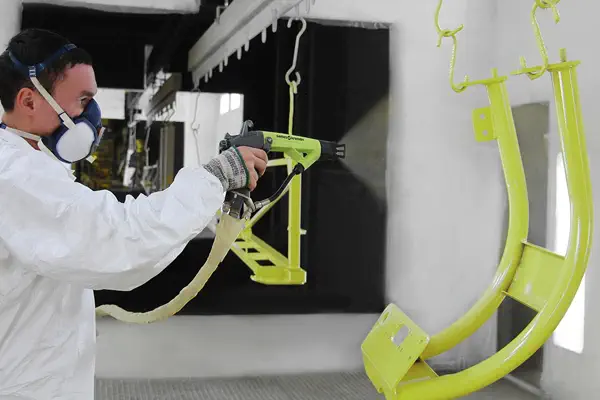

Quality Control of Outer Protective Spraying

- Shot blasting sand removal: Before spraying construction machinery and equipment, we will use shot blasting sand to remove rust from the raw materials to ensure that there is no dirt or rust on the surface of the workpiece to be sprayed.

- Modulated paint: We will configure the color of the paint according to the customer's customized needs. Construction machinery and equipment usually use yellow, black, orange, green and other colors as the first choice for outer coating. Customers can also personalize the exterior paint color.

- Paint baking: Strictly controlling the baking temperature of paint is the key to ensuring the effect of paint spraying. Too high and too low temperatures will lead to problems such as reduced paint adhesion and darker colors.

Strict organization of various accessories

- Develop organizational process flow: Each piece of engineering machinery and equipment has a detailed and clear process flow for assembly, including assembly sequence, method, torque requirements, installation cleaning and other steps to ensure that each component can be installed correctly

- Double inspection: Each installation step of construction machinery and equipment will be inspected by more than two quality inspection personnel. The next step of installation will be continued only after the previous step of installation is correct.

Engineering machinery equipment performance testing

- Professional performance testers: Our construction machinery equipment testers have many years of work experience and are very familiar with various types of construction machinery and equipment, and can comprehensively conduct performance testing of the construction machinery equipment to be tested.

- Strict testing procedures: Each construction machinery equipment test has strict testing procedures, including the test sequence, duration and corresponding performance data collection.

Final inspection before product delivery

- Appearance integrity inspection: Before shipment, we will conduct a comprehensive inspection of the appearance of the construction machinery and equipment to ensure that there are no scratches, spots, color differences and other defects.

- Proper shipping packaging protection: Before shipment of some construction machinery and equipment, we will use special wooden boards for frame protection to ensure that the equipment will not be bumped during shipping.

Have Anything To Ask Us?

Please fill in your email in the form and we’ll get back to assist you soon!

- Will contact you within 1 hour.

- Don't worry, we hate spam too!